Transforming Agriculture with Cutting-Edge Grain Monitoring Technologies

In today’s rapidly evolving agricultural landscape, the integration of innovative grain monitoring systems has become a cornerstone for farmers seeking to maximize efficiency, improve crop quality, and enhance overall farm profitability. As the industry becomes more data-driven, the importance of reliable farming equipment and comprehensive farm equipment repair services cannot be overstated. Leading providers like tsgcinc.com are at the forefront, offering groundbreaking solutions tailored to modern farming needs.

Why Grain Monitoring Is a Game-Changer in Modern Agriculture

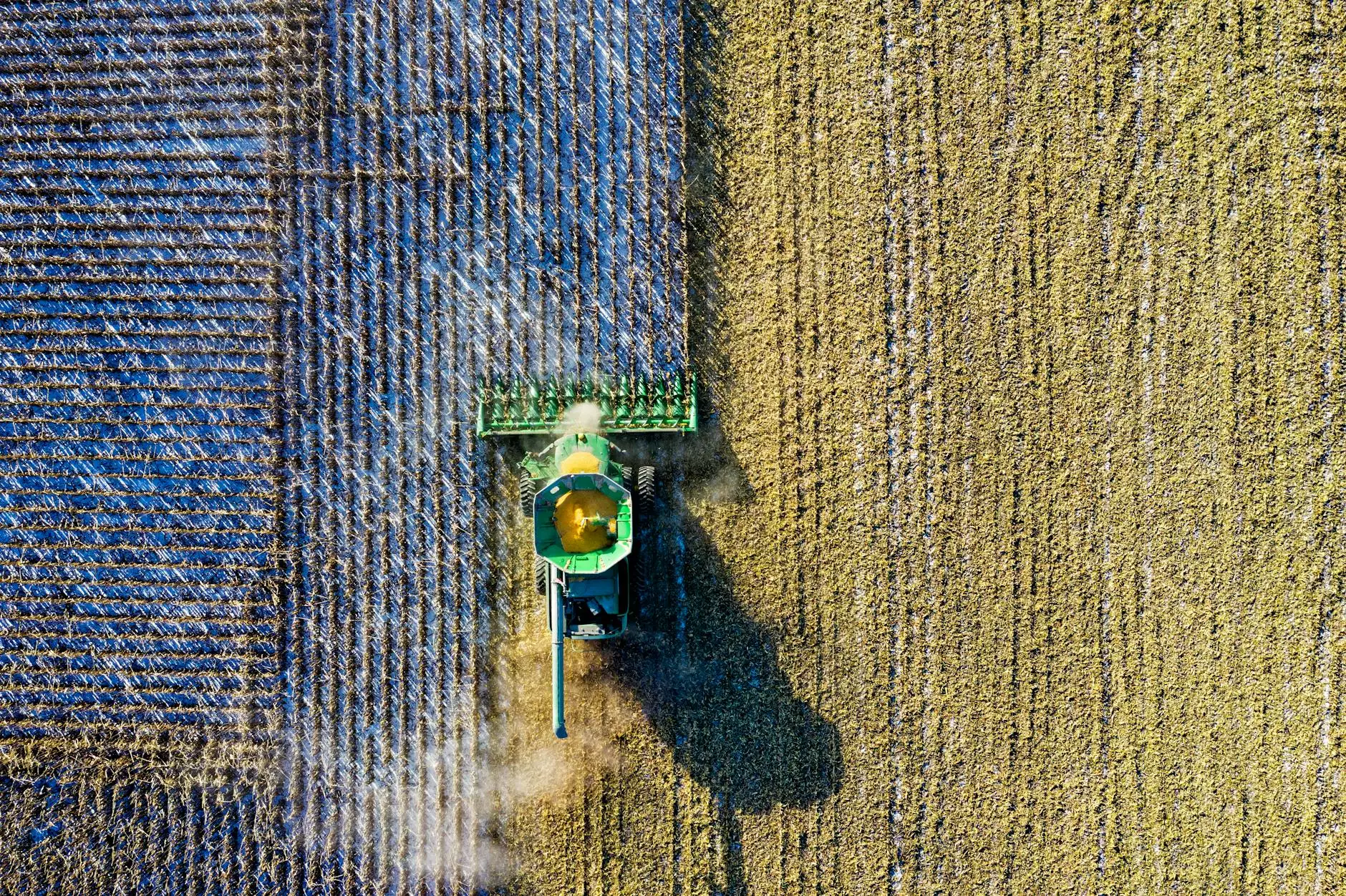

Grain monitoring systems are sophisticated technological tools designed to provide real-time insights into crop storage conditions, post-harvest processes, and on-field grain health. By deploying these systems, farmers gain unparalleled visibility into their grain inventory, enabling proactive decision-making that minimizes loss and maximizes quality.

Traditional methods relied heavily on manual inspections and estimations, which often resulted in inconsistencies, spoilage, and inefficiencies. Today, state-of-the-art grain monitoring solutions leverage sensors, IoT devices, and advanced analytics to deliver precise data. This technological shift not only improves operational efficiency but also enhances sustainability and environmental stewardship.

The Impact of Grain Monitoring on Farming Equipment and Maintenance

An often-overlooked benefit of integrating grain monitoring is its positive influence on farming equipment performance and maintenance schedules. Equipment such as grain bins, dryers, conveyors, and harvesters operate more effectively when monitored continuously. Sensors can detect issues like temperature fluctuations, humidity levels, or pest activity that may compromise grain quality.

By implementing proactive farming equipment repair based on data from grain monitoring systems, farmers can prevent costly breakdowns and extend the lifespan of critical machinery. For instance, identifying abnormal temperature increases early helps avoid bin fires or spoilage, ensuring the safety of both personnel and assets.

The Essential Role of Farm Equipment Repair in Grain Storage & Post-Harvest Success

The efficiency and longevity of your farming equipment directly influence the success of your grain management strategies. Regular farm equipment repair is vital for maintaining optimal operation of vital machinery used in grain drying, storage, and transportation.

Advanced grain monitoring systems work in tandem with high-quality repair services. When equipment malfunctions are detected early, whether through automated alerts or routine inspections, prompt repairs safeguard crop quality, reduce energy consumption, and cut down on downtime.

Benefits of Integrating Grain Monitoring with Farm Management Systems

- Enhanced Data Accuracy: Precise, real-time data on grain conditions leads to better decision-making.

- Improved Crop Quality: Consistent monitoring helps maintain optimal storage conditions, reducing spoilage.

- Operational Efficiency: Automated alerts and analytics optimize harvest timing, drying processes, and maintenance schedules.

- Cost Savings: Preventive maintenance minimizes unexpected repair costs and prolongs equipment lifespan.

- Environmental Stewardship: Efficient energy use and reduced grain waste contribute to sustainable farming practices.

Innovative Technologies in Grain Monitoring: A Deep Dive

Modern grain monitoring solutions employ a suite of technological innovations, including:

- Sensors and IoT Devices: Deployed inside grain bins and storage facilities to continuously track temperature, humidity, and pest activity.

- Data Analytics and Cloud Computing: Aggregate data from multiple sensors for comprehensive analysis and accessible dashboards.

- Wireless Connectivity: Facilitates real-time alerts via smartphones or control centers, enabling swift responses.

- Integration with Farm Management Software: Seamlessly links monitoring data with operational workflows for streamlined farm operations.

- Automated Climate Control Systems: Adjust drying fans, vents, and other equipment based on sensor data, ensuring optimal storage conditions.

Case Study: Boosting Farm Productivity with Grain Monitoring and Equipment Maintenance

Consider a Midwest grain farm that adopted comprehensive grain monitoring systems alongside a proactive farm equipment repair program. By installing sensors in storage bins and integrating the data with their equipment controls, the farm experienced notable improvements:

- Reduction in grain spoilage: Moisture and temperature monitoring led to timely drying and aeration, preserving grain quality.

- Decreased maintenance costs: Predictive diagnostics identified early equipment wear, enabling targeted repairs.

- Enhanced operational efficiency: Automated alerts minimized manual inspections and optimized harvest timing.

- Increased profitability: Higher quality grain and reduced losses directly contributed to increased revenue.

Choosing the Right Grain Monitoring System for Your Farm

Selecting an appropriate grain monitoring system requires careful consideration of several factors:

- Scale of operations: Larger farms benefit from scalable solutions that can handle extensive storage facilities.

- Type of crops and storage conditions: Tailored sensors and protocols may be necessary for different grain types.

- Integration capabilities: Compatibility with existing farm management software and machinery enhances efficiency.

- Ease of use and support: User-friendly interfaces and reliable customer service are critical for long-term success.

- Cost and ROI: Evaluate initial investment against potential savings and productivity gains.

Partnering with Industry Leaders: Why Choose TSGC Inc.?

As a proven leader in Farm Equipment Repair and Farming Equipment solutions, TSGC Inc. offers unmatched expertise in integrating advanced grain monitoring technologies. Their comprehensive approach ensures that your farm benefits from:

- Expert installation and setup of monitoring systems

- Ongoing maintenance and rapid farm equipment repair

- Customized solutions tailored to your specific farm operations

- Comprehensive training to maximize system utilization

- Robust customer support and innovation-driven updates

The Future of Grain Monitoring in Agriculture

The trajectory of grain monitoring technology points toward an increasingly intelligent, interconnected, and autonomous farming ecosystem. Leveraging advances in artificial intelligence, machine learning, and automation, future systems will predict issues before they arise, optimize storage conditions automatically, and fully integrate with autonomous machinery.

Farmers embracing these innovations not only stay ahead of the competition but also contribute to a more sustainable and efficient agricultural industry. The fusion of farming equipment excellence with innovative monitoring tools creates a powerful synergy that can transform farm productivity and profitability for years to come.

Conclusion: Elevate Your Farming Enterprise with Expert Grain Monitoring & Equipment Solutions

Investing in grain monitoring technology and maintaining your farming equipment through reliable farm equipment repair services represent strategic moves for modern farmers. These tools and services empower you to make data-driven decisions, prevent costly losses, and enhance crop quality—ultimately driving your farm towards greater success and sustainability.

To learn more about how TSGC Inc. can help you implement state-of-the-art grain monitoring solutions and expert equipment repair services, visit tsgcinc.com. Embrace the future of agriculture today and reap the benefits of a smarter, more resilient farming operation.